Aerospace specialties

Our metalworking range for AEROSPACE is designed to optimize performances and productivity with respect for materials, users and the environment.

Solutions for structural part machining

The philosophy underlying the formulation of a machining fluid is to meet the strictest requirements in terms of hygiene and safety, ease of maintenance, while ensuring machining performance. The use of high-performance machining fluids allows for significant savings and increased productivity, particularly for structural components requiring high material removal rates.

MotulTech offers several water-soluble fluids for working on parts made of various alloys, meeting the SAFRAN PR 6300, BOEING BAC 5008, AIRBUS AIMS 12-10-000, AIMS 12-10-001, AIMS 12-10-003 requirements :

- BIOCOOL 3740 - Synthetic fluid suitable for the machining and grinding of aeronautical aluminum.

- SAFKOOL 6820 SW - Boron-free micro-emulsion suitable for the machining of aeronautical aluminum, titanium, and TiAl.

- SAFKOOL 6920 CS - Boron-free micro-emulsion suitable for the machining of aeronautical aluminum, titanium, and TiAl.

- SAFKOOL 6950 GV - Boron-free micro-emulsion, vegetable-based, with no safety labeling, suitable for the machining of titanium and TiAl.

- STABILIS 9230 - High-pressure emulsion suitable for the machining of aeronautical aluminum, titanium, and TiAl.

- STABILIS 9827 MG - Boron-free emulsion suitable for the machining of aeronautical aluminum, titanium, TiAl, and Inconel.

- STABILIS 9857 - Boron-free emulsion suitable for the machining of aeronautical aluminum, titanium, and Inconel.

- STABILIS 9830 - High-pressure, boron-free emulsion suitable for the machining of aeronautical aluminum, titanium, TiAl, and Inconel.

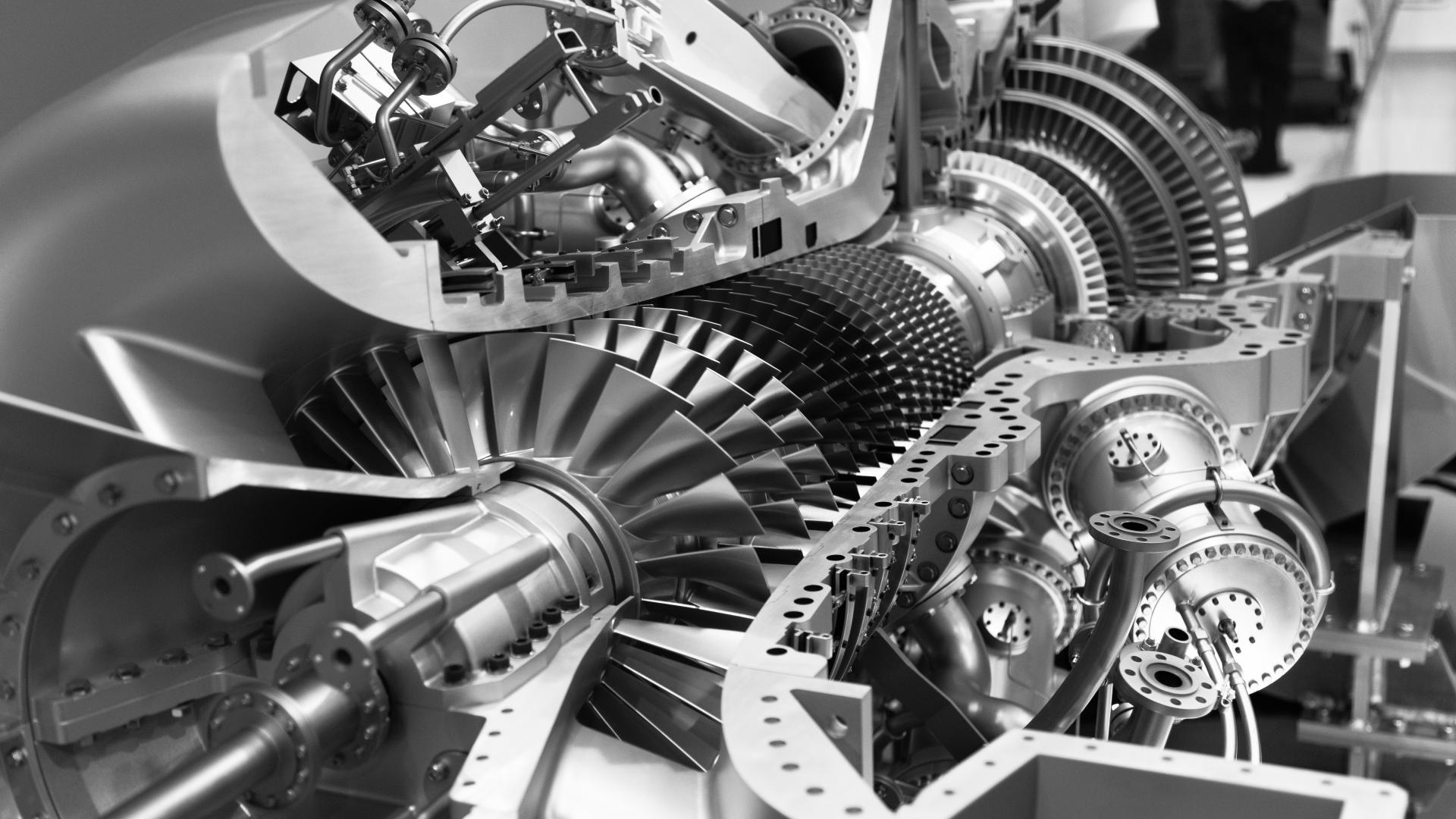

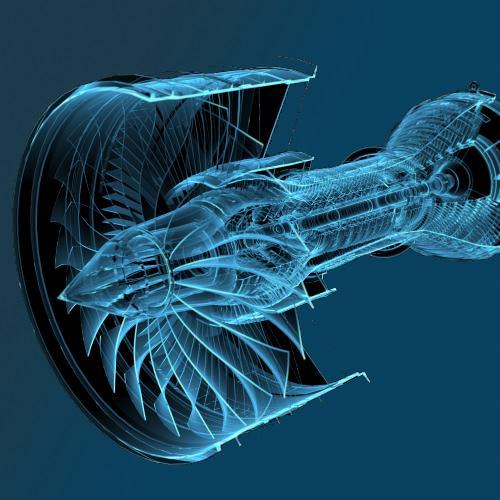

Solutions for engine part machining

The machining of metals with poor machinability requires the use of cutting fluids that offer very high cooling performance while ensuring an excellent level of lubrication. The application of cutting fluid under high pressure and the high flow rates are also challenges. Thanks to a rigorous selection of the latest generation of additives, MT products can meet these challenges for the manufacturing of parts intended for the hot sections of engines.

MotulTech offers several water-soluble and neat fluids for working on nickel and titanium alloy parts that meet SAFRAN PR 6300, BOEING BAC 5008, AIRBUS AIMS 12-10-000, AIMS 12-10-001, AIMS 12-10-003 requirements:

- BIOCOOL 3220 - Synthetic fluid suitable for the machining and grinding of Inconel and titanium

- SAFKOOL 6820 SW - Boron-free micro-emulsion suitable for the machining of aeronautical aluminum, titanium, and TiAl

- SAFKOOL 6920 CS - Boron-free micro-emulsion suitable for the machining of aeronautical aluminum, titanium, and TiAl

Solutions for metal part cleaning

Ubiquitous in workshops, cleaning products must offer optimal cleaning performance while

presenting the least possible risk for the industrialist and the users.

They must meet several requirements: degreasing power, drying speed, high flash point, controlled health & safety risk.

The new cleaners' formulas make possible to combine seemingly contradictory requirements.

The first of these requirements is efficiency : the cleaning and degreasing of parts must be quick and complete and leave flawless and damage-free parts. Then the product should dry quickly without leaving deposits. Finally, its use must not present a risk for the operators, and the flash point of the product must be chosen according to the context of use.

The MotulTech range offers a range of solutions that cover most industrial needs, in perfect compliance with current legislation.